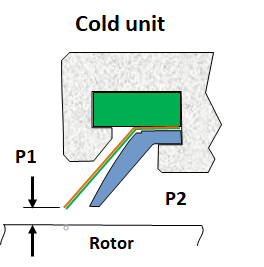

Large cold clearence

- P1 = P2

- Seal elements not in contact with support

- Seal rubs avoided

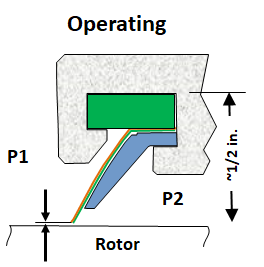

Small operating clearance

- P1 >> P2

- Seal elements in contact with support

- Minimum leakage for performance gain

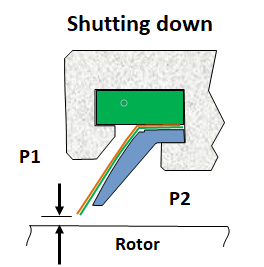

Increased shut down clearance

- Δ P decreasing with RPM.

- Seal elements retract from support.

- Seal rub damage avoided.